-

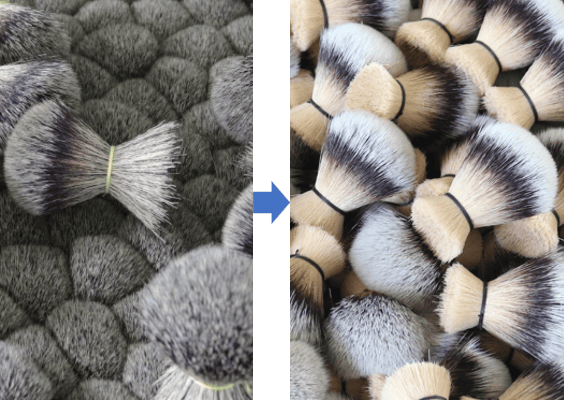

01 Manual Visual Inspection of hairs (QC 1)

A. Manual inspection of the waviness, peak, color, and length of hairs. (QC 1)

B. Hairs of 4 waviness with fixed portions make each JDK brush with perfect density and a naturally beautiful shape, similar to a badger.

C. Medium peak hairs ensure the best touch effect on the skin, similar to a badger. -

02 Weighing hairs (QC 2)

A. 20 grams of bristle hairs in each brush. (QC 2)

B. Weighing with precision electronic scales makes each brush from the same batch with the same density, shape, and weight. -

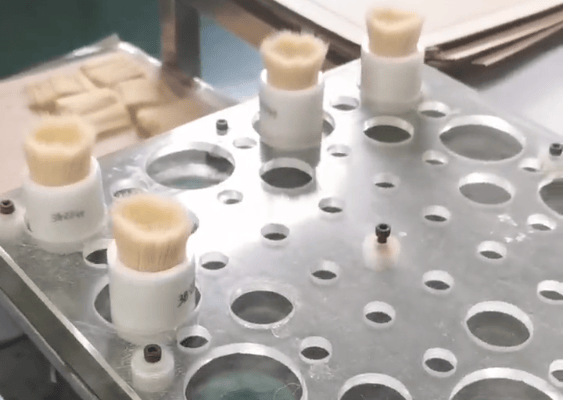

03 Vibrate the hairs in cups

Vibrate the hairs both manually and semi-automatically in custom cups to ensure the best shape of the brush.

-

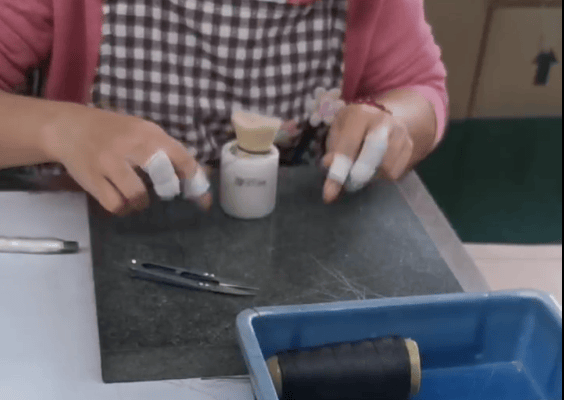

04 Rope the hairs

Rope the hairs to get better shape, then shape the hairs

-

05 Fill hair bunch into the tube

Fill hair bunch into the tube

-

06 Shape the hair bunch

Shape the hairs again to get more natural beautiful shapes of brushes.

-

07 Measure the whole height of the knot, adjust the hair

This makes sure JDK shaving brushes get the same height.

-

08 Drop glue onto the root of the hair bunch

JDK has 2 tips to avoid shedding here.

-

09 Reshape the hair bunch

Shape the hairs for a third time to get better shapes of brushes.

-

10 Pull hairs manually (QC 3)

Get rid of any knots with shedding. (QC 3)

-

11 Untie the rope on the bunch (QC 4)

Get rid of any knots with glue leaks. (QC 4)

-

12 Fill the Knot handles

Fill the Knot handles

-

13 Manual inspection on handles (QC 5)

Get rid of any handles with quality problems. (QC 5)

-

14 Put the shaving brushes in a PP bag or tube (QC 6)

Avoid the knots from deformed, and avoid handles from scratches. (QC 6)

-

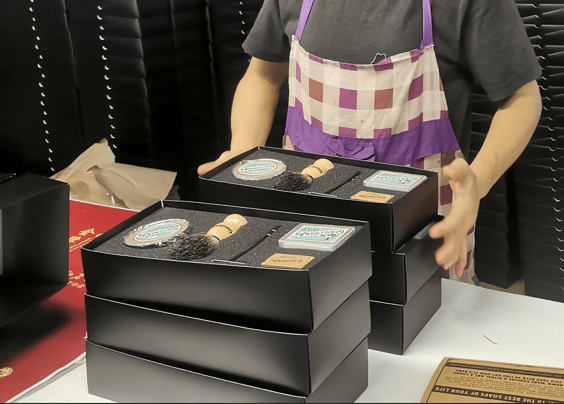

15 Packaging

Packaging

Key Steps in Shaving Razors Production

Explore our precision-crafted razor manufacturing process for a superior classic shaving experience. We source premium-quality materials, provide tailored designs and prototypes, employ cutting-edge precision machining or mold, and apply expert surface treatments to create high-performance wet shaving tools. Our skilled craftsmen meticulously assemble each razor and razor accessories, ensuring excellence and durability. Stringent quality control measures guarantee consistency.

Partner with us for precision, quality, and innovation in men's grooming razors.

-

Material Selection

-

Design and Prototyping

-

Tooling and Die-Casting

-

Machining

-

Surface Finishing

-

Assembly

-

Quality Control

-

Packaging